Product Description

Principle of Ultrafiltration Equipment

Ultrafiltration technology is a kind of membrane filtration method. It uses asymmetric microporous structure and semi-permeable membrane medium at a certain pressure and flow rate at room temperature, and relies on the pressure difference between the two sides of the membrane as the driving force to filter in a cross-flow manner. Solvents and small molecular substances pass, and macromolecular substances and fine particles such as proteins, water-soluble polymers, bacteria, etc. are retained by the filter membrane to achieve separation, classification, purification, and concentration. A new type of membrane separation technology.

Product Parameters

|

1200TPD Container Ultrafiltration Equipment |

|

| Model | WY-UF-1200 |

| Water yield | 50m3/hr |

|

Recovery rate |

90% |

| Inlet water temperature |

5~45℃ |

| Product water turbidity | <0.1NTU |

|

SDI |

<1 |

| Power |

AC380V / 50Hz / Three phase |

|

Dimensions |

40 feet container |

|

Net weight |

8,900KG |

|

Power |

11KW |

* 1. Equipment can be customized according to customer requirements.

Equipment list

1. Water treatment equipment

2. User manual, Operation video*

3. Final document (product certificate, factory test report, packing list, equipment drawing)

4. Other consumables accessories

Please contact us for more details.

Mobile: +86 133 2668 2480(Steve)

Mobile: +86 133 2668 2480(Steve)

+86 133 2665 7486(Abey)

Whatsapp: +86 137 9898 8771(Steve)

Whatsapp: +86 137 9898 8771(Steve)

+86 159 1922 3536(Abey)

abey@zhwywater.com

Component drawing:

|

|

|

| UF System |

Precision Filter |

Self-cleaning Filter |

|

|

|

| CEB Cleaning System |

Rinse Tank |

Control Cabinet |

|

|

|

| Feed Pump |

Backwash Pump |

Water Flow Meter |

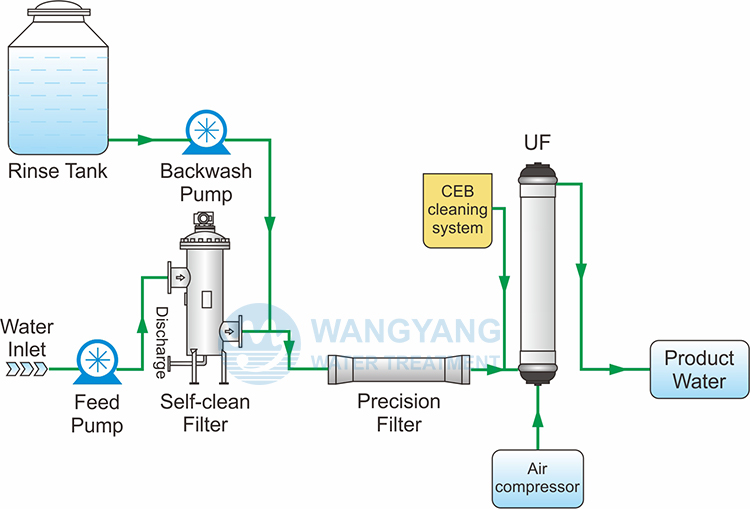

Process flow diagram

Features

1. The ultrafiltration process is carried out at room temperature with mild conditions and no component damage, so it is particularly suitable for the separation, classification, concentration and enrichment of heat-sensitive substances, such as drugs, enzymes, fruit juices, etc.

2. There is no phase change in the ultrafiltration process, no heating, low energy consumption, no chemical reagents, no pollution, and it is an energy-saving and environmentally-friendly separation technology.

3. Ultrafiltration technology has high separation efficiency and is very effective for the recovery of trace components in dilute solutions and the concentration of low-concentration solutions.

4. The ultrafiltration process only uses pressure as the power of membrane separation, so the separation device is simple, the process is short, the operation is simple, and it is easy to control and maintain.

Applicable field

1. Water treatment industry: removal of suspended solids, tiny particles and bacteria in water;

2. Electronics industry: terminal treatment of ultrapure water for semiconductor industry and cleaning water for integrated circuits;

3. Pharmaceutical industry: medical pure water sterilization, pyrogen removal, and drug sterilization;

4. Medical industry: remove bacteria in tissue fluid, antibiotics, serum, plasma protein and other solutions;

5. Food industry: Removal of suspended matter, microorganisms and odor impurities, yeast and mold in beverages, wines, soy sauce, vinegar and other foods, and juice clarification and filtration.

6. Chemical industry: filtration and clarification of various chemicals.

7. Special industries: widely used in the treatment of spray paint wastewater, metal processing wastewater and food industry wastewater and the recovery of useful substances in the automobile manufacturing industry.

Email:

Email: