Boiler supply water

After various methods of purification, the raw water is used to supplement the water lost in the water and steam circulation system of the power plant.

The natural water without purification contains a lot of impurities, if this kind of water enters the boiler directly, it will cause all kinds of harm, such as scaling and corrosion of the equipment, which also threatens the safety of the staff in the factory.

Therefore, in order to ensure good water quality in the thermal and power system, it is necessary to properly purify the natural water and strictly supervise the quality of steam and water.

Boiler supply water system

The main task of using boiler supply water system to treat the water before entering the boiler is to ensure the supply of sufficient quantity and qualified desalted water in order to ensure the safe and stable operation of the unit.

The boiler supply water system provided by our company has high salt rejection rate and water reuse rate of 95%. It has become the preferred boiler supply water system for many heating companies and power plants.

The boiler supply water treatment system is designed with reverse osmosis pre-desalting system.

Boiler supply water treatment system consists of two parts: pre-desalting system and ion exchange desalting system.

The pre-desalting system includes ultrafiltration system, reverse osmosis system, dosing system, chemical cleaning system, compressed air system and so on.

Ion exchange desalination system includes ion exchange system, acid-base regeneration system, compressed air system, wastewater neutralization treatment system and so on.

The boiler supply water treatment mode is filtration, ultrafiltration, reverse osmosis pre-desalting, first-stage desalting and mixed bed treatment system.

Process: pretreatment + RO (reverse osmosis) + mixed bed.

Please contact us for more details.

Mobile: +86 133 2668 2480(Steve)

Mobile: +86 133 2668 2480(Steve)

+86 133 2665 7486(Abey)

Whatsapp: +86 137 9898 8771(Steve)

Whatsapp: +86 137 9898 8771(Steve)

+86 159 1922 3536(Abey)

abey@zhwywater.com

Reverse Osmosis Technology

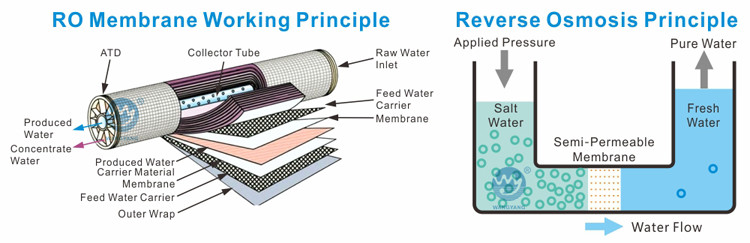

Pure water desalination is the process of separating substances with a semi-permeable membrane under pressure. The reverse osmosis membrane surface activity only allows water to permeate, 99% soluble salt and all bacteria and impurities are trapped, and water has no phase change, so reverse osmosis desalination is the most advanced and energy-saving method of desalination.

The reverse osmosis membrane is an artificial semipermeable membrane made of a semi-permeable membrane that has certain characteristics and is a core component of reverse osmosis technology.

The principle of reverse osmosis technology is to remove these substances and moisture according to the osmotic pressure of the solution, according to the fact that other substances cannot pass through the semipermeable membrane. The membrane pore size of the reverse osmosis membrane is very small, so that dissolved salts, colloids, microorganisms, organic matter, and the like in the water can be effectively removed.

The system has the advantages of good water quality, low energy consumption, no pollution, simple process and easy operation.

Customer cases

|

|

|

Pure water treatment equipment for food and beverage industry project case |

Raw Water Quality

TDS: ≦700mg/L

Inlet Temperature: 5~45℃

Product Water Quality

TDS: <50mg/L

Desalination Rate: ≧99.8%

Operating Pressure: 0.6-2.2MPa

Power

Voltage: 220V / 380V /440V, 50~60HZ, Three-phase

Protection Levels: IP54

Please contact us for more details.

Email: steve@zhwywater.com, wy@zhwywater.com

Tel:+86-756-8930698

Mobile:+86-13326682480

Email:

Email: